Simply more reliable |

News

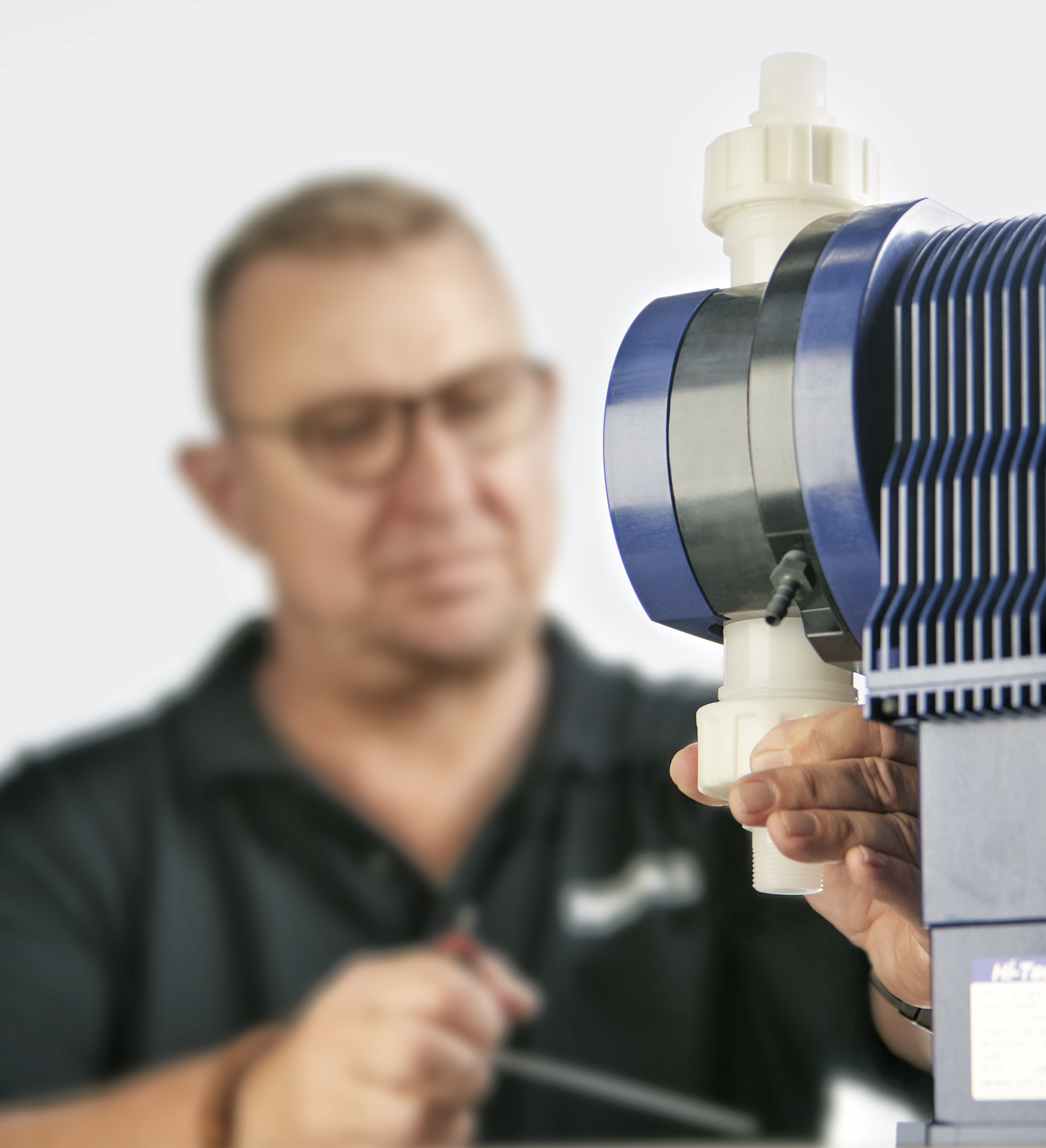

Introduction of two new and powerful

pump sizes in the MDM series

April 9th, 2021

IWAKI adds two mag-drive pumps to the MDM series.

The new pump sizes are very efficient and deliver i.a. a larger flow.

Read more…

IWAKI Nordic A/S

Roennekrogen 2

DK-3400 Hilleroed

Phone +45 48 24 23 45

E-mail [email protected]